Well OK it’s still not on 4 wheels… but it’s getting there. I got the body off the AutoTwirler and back on to the rebuilt front subframe

…

Archive:

Subframe

Finally… an update!

So, where the car stands… 2 noise complaints from the council down the line, all the grinding of welds is done. The body and panels have been shotblasted again and not by a cowboy with an air compressor and a bucket of sand, this time hopefully by a professional. Everything is primered in Eastwood epoxy.

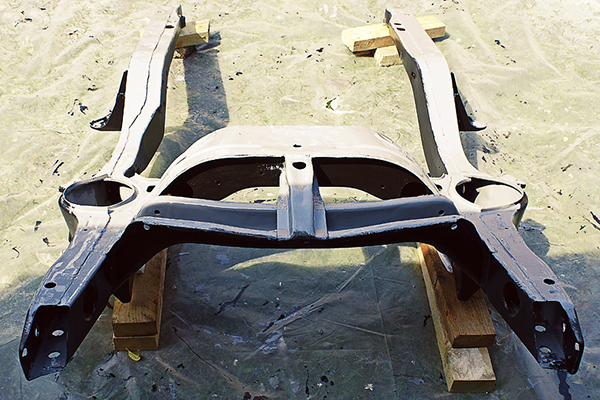

Before:

During:

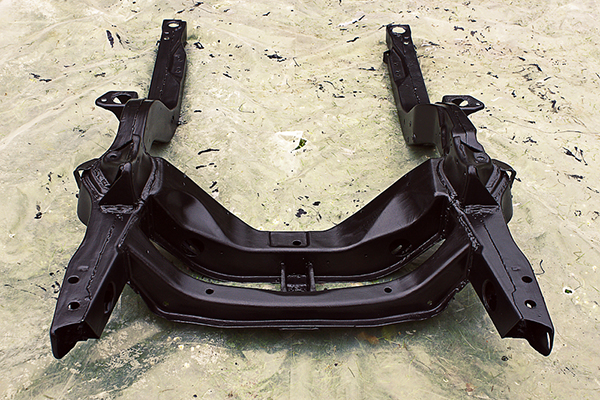

Now:

The subframe has been fully rebuilt with new…

Rebuilding subframe. Upper control arms.

Installing new bushings.

I don’t have access to a press, so a hammer had to suffice. To install them, start with positioning one bushing in place, then slide the shaft into the inner sleeve, then position the other bushing with the other end of the shaft going into this inner sleeve. I used one the my old bushing shells to hit these new bushings as it was a good fit,…

Rebuilding subframe. Steering center link.

Rebuilding the steering linkage.

Started by bolting the steering gearbox to the subframe. This is held on by 3 bolts.

Then I found the old tie-rods and assembled the new ones to roughly the same length.

Then attach them to the centre-link.

Last bits to attach to the centre-link are the pitman arm and the idler arm. Once these are on the centre-link it is just…

Cavity waxing.

For this I used Bilt Hamber Dynax S-50 (anti-corrosion for cavities). Only way to tell if it’s really any good is to wait a few years. It certainly applied easily and got good coverage, and is definitely water repellent. When it dries it has a rubbery flexible feeling.

Subframe inside. Before and After:…

Painting subframe (underneath).

POR-15 (rust preventative base coat):

The base coat is really good stuff. Goes a long way and all brush strokes smooth out when drying.

POR-15 Chassis-Coat (UV protection top coat):

The top coat is not quite as good as the base. It covers about half as much, and brushes strokes are inevitable. It does have a nice finish – colour and sheen – to it though. Once the subframe…

Painting subframe.

POR-15 (rust preventative base coat):

The base coat is really good stuff. Goes a long way and all brush strokes smooth out when drying.

POR-15 Chassis-Coat (UV protection top coat):

The top coat is not quite as good as the base. It’ll cover about half as much, and brushes strokes are inevitable. It does have a nice finish – colour and sheen – to it though. Once the subframe…

Cleaning subframe.

To strip all the subframe parts is kinda lengthy, and I forgot to take pictures. It is pretty simple: Remove the front wheels. Remove the shocks. Split the tie-rods and unbolt the steering pump and idler arm (entire steering assembly). Remove the sway bar. Chain the coil spring to the lower control arm and split the lower ball joint. Split the upper ball joint. Unbolt upper and lower control arms.…

Separating front subframe.

Once the engine and transmission are out, the subframe could be unbolted in four location from the body – 2 under the front seat pans and 2 directly under the firewall/bulkhead. These were very rusty so a big cheat bar on the socket wrench was used, and probably a whole can (not really…) of WD-40. The bushings are completely shot, there’s almost nothing left of them, they’ve rusted and disintegrated…

;)

;)

;)

;)

;)

;)

;)