Archive:

Rust removal / prevention

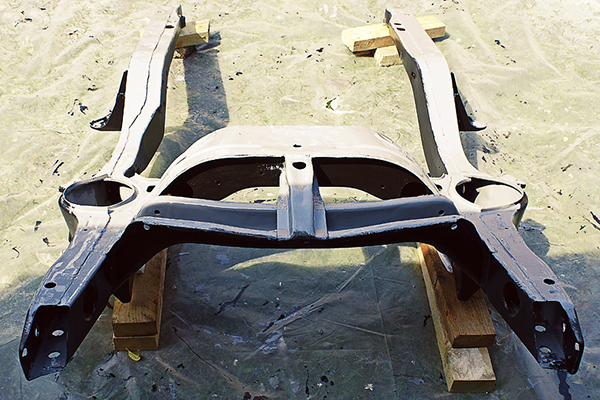

Prepping batch of parts for POR-15 paint.

The latest batch of parts to be painted. Sadly not the last.

1 – Marine Clean applied by spray bottle. 2 – Jet blast Marine Clean off. 3 – After degreasing.

Forgot about the axle, so time to degrease that.

Nice picture showing the colour of the degreasant being blasted off, obviously works.

Drying after being degreased.

Time to pre-prime with Metal Ready. Again applied…

…Yet more rust removal. Shot blasting this time.

First of all was to separate the steering centre-link from the idler arm, pitman shaft, and old tie-rods.

This is as simple as removing a pin, undoing a nut, knocking with a hammer and repeating. Easier said than done with something this rusty.

And afterwards:

Had the sway bar and, now, the centre link to grind the rust away.

With most of the rust gone on most of…

Some hocus pocus. And more rust removal.

The hocus pocus:

Had lots of little parts, with lots of rust that needed to be removed. Best way is to use a dip solution. I used Bilt Hamber Laboratories Deox C concentrated rust remover. It is a white powder that gets diluted in water (yes, water). A kilo of this powder can make up to 20 litres of rust removing solution. I found this to be very effective and…

Whole Lotta Rust (removal).

Spent today breathing in lots of rust dust. I had planned on shot-blasting away most of the rust with the thought that a new compressor and gun would make the job a piece of cake. It is still very time consuming and tedious, so to speed it up I’ve used a flap wheel on an angle grinder to get most of the rust away, then plan to use the shot-blaster…

Cavity waxing.

For this I used Bilt Hamber Dynax S-50 (anti-corrosion for cavities). Only way to tell if it’s really any good is to wait a few years. It certainly applied easily and got good coverage, and is definitely water repellent. When it dries it has a rubbery flexible feeling.

Subframe inside. Before and After:…

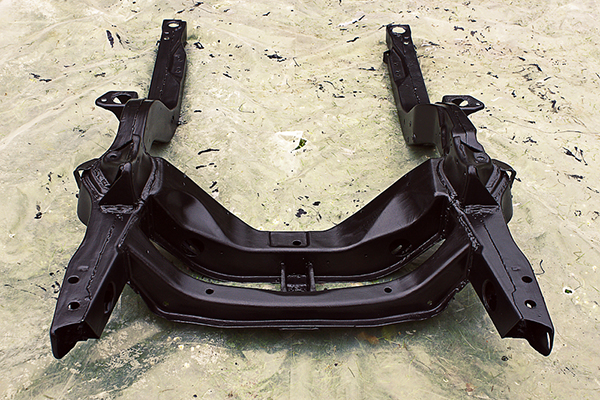

Painting subframe (underneath).

POR-15 (rust preventative base coat):

The base coat is really good stuff. Goes a long way and all brush strokes smooth out when drying.

POR-15 Chassis-Coat (UV protection top coat):

The top coat is not quite as good as the base. It covers about half as much, and brushes strokes are inevitable. It does have a nice finish – colour and sheen – to it though. Once the subframe…

Painting subframe.

POR-15 (rust preventative base coat):

The base coat is really good stuff. Goes a long way and all brush strokes smooth out when drying.

POR-15 Chassis-Coat (UV protection top coat):

The top coat is not quite as good as the base. It’ll cover about half as much, and brushes strokes are inevitable. It does have a nice finish – colour and sheen – to it though. Once the subframe…

;)

;)

;)

;)

;)

;)

;)

;)

;)