Apologies for the complete lack of posts in 2012! – progress is not quite as ongoing as I would’ve hoped… Anyway, last summer I purchased a cast iron 4bbl intake (not date correct, but that doesn’t bother me too much). Here it is:

This was a typical eBay “perfect working condition”… clear, heavy rust pitting at the exhaust crossover and water ports. My engine shop suggested any milling might be detrimental to the alignment so I have “restored” the surfaces using only epoxy and block sanding. This manifold isn’t a great choice but they are incredibly hard (i.e. impossible) to find over here, so this one from the States looked to be in as good a condition as the few others available and at just a steep price – so I either keep this or go back to the aluminium Edelbrock which I really don’t like… I installed it using new ARP bolts – much better than the last set whose head flanges were far too small.

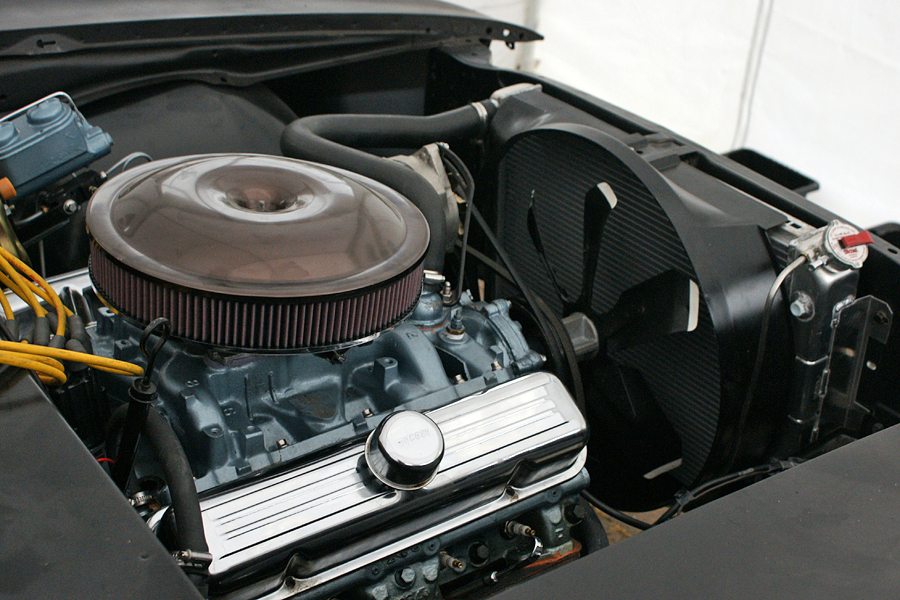

At the same time I replaced the original pushrods and rockers with CompCams roller-tips (1.52 ratio). I wanted to use poly-lock nuts but this isn’t possible without shortening my rocker studs, so I am using the supplied set of standard rocker nuts, adjusted to zero lash plus a half turn.

Also, the radiator leaked fluid out the line fittings so was replaced. This was also an opportunity to swap out the fluid lines with a stainless steel set.

After all this, the engine was started. What a difference the cast iron intake makes to the sound. So much more to the noise, deeper, more growl and more throaty. Much better!

But, the idle still surges. Any number of potential causes… The surging idle, relative difficulty starting, fluctuating and maybe slightly low vacuum (although this changes with the idle) points to a vacuum leak. Not my last post jumped the gun. I did have steady strong idle and vacuum – but this was idling at 800rpm a silly oversight on my part, idle should be around 600/650rpm, at which point the idle surges. The wonderfully restored manifold was near the top of my list of things to check this time round, but there was no sign of a vacuum leak around any of the edges or bolts or or fittings or the surface (flammable spray method). After failing to remedy it, the car was packed up for winter…

Until this past week when I had time to quickly perform a rather crude vacuum leak smoke test – and I do mean crude, I wouldn’t recommend this at all. Out of desperation here is what was knocked up… the smoke source was a smoke pellet – the kind used to test for chimney obstructions – and is a very dirty smoke and will leave residue and potentially clog up the internals. But I wasn’t too keen on heating up mineral oil with a glow plug to get a cleaner smoke, so this would do, only briefly.

The carb top was blocked off and smoke was introduced into the brake booster outlet at the back of the carb using a compresser to push, at a trickle of a few PSI. Immediately as soon as the smoke went in, it poured out the secondary throttle shafts. Pointing to improperly seated or aligned throttle plates.

At risk of simply throwing money at the problem I want to buy a professionally rebuilt carb. The little time I find makes the lack of progress sometimes frustrating, so I feel this is the best bet to sort the problems out or at least definitively rule out one source of them. Until then…

Hey I was reading how you said your idle should be around 650. But it sounds like you have an aftermarket cam with a more agrressive cam profile. If its not a stock cam then you might be beating yourself up about the idle speed being a tad bit higehr. A more aggressive cam will need a higher idle speed. I have this same situation. It smooths itself out at a higer idle speed. It makes sense because my cam has a power range from 1900 to 5500 rpm. Just a thought. I hope it helps.