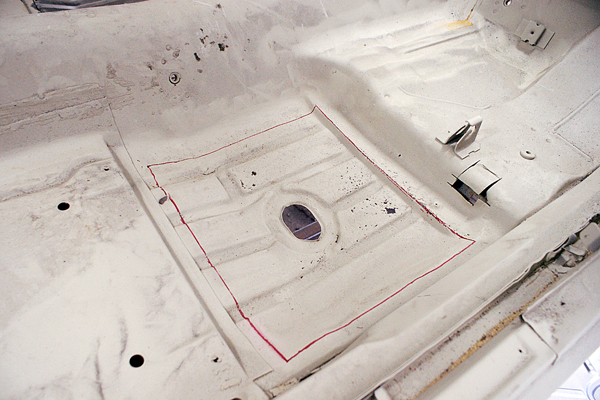

There were too many little rust holes to patch up, so the whole floor is to be replaced. First was to decide and mark out how much of the old floor to cut out.

Then, the cut out section is overlaid on the new floor pan and drawn around. Then enlarge the outline by about an inch or so all around and cut out the new pan.

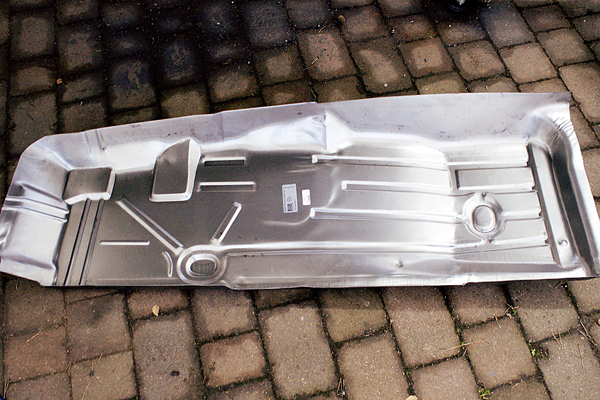

The new floor pan. Laid onto the car to see if any more trimming needs to be done and to mark out the boundries for where the paint needs to be stripped on the car. Note that the cutout I made a while ago when removing the leaf springs now gets patched up by the new floor pan.

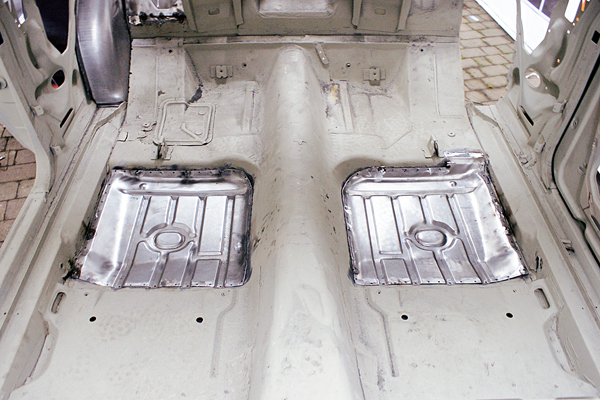

The paint stripped from the body, now ready to be welded. I’ve marked on the new pan every 1.5 inches where a hole will be drilled or punched for the plug welds. Then once all the holes have been made, grind the holes and cut edges clean.

The new pan is now ready to be welded in place. I’ve only tacked it (and the other side) in a few places for now but all the holes will be plug welded shortly… And possibly seam welded for an inch between the plugs for extra strength, but I’m considering whether or not this is needed.

No comments yet.