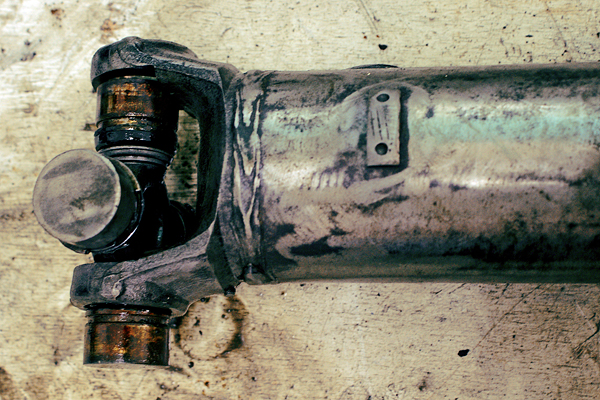

The driveshaft universal joint to be removed. This doesn’t rotate smoothly – it’s very clunky – so a new one will be installed after the shaft is painted.

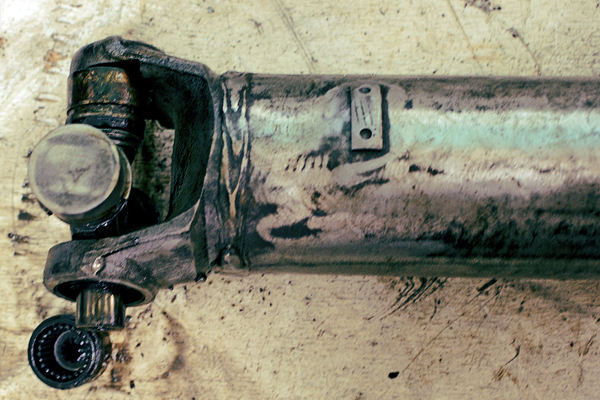

First step is to remove the retaining C-clips. Any tool with a point will do for this.

Now the u-joint will be able to move (forcibly, not freely) for the next step. Put a socket larger than the u-joint bearing cap underneath, like shown, and a smaller one on top, also like shown. Hit the top, smaller, one and the whole u-joint will move down with the bottom bearing cap going into the larger socket. Once the lower cap is out of the drive shaft it can be removed.

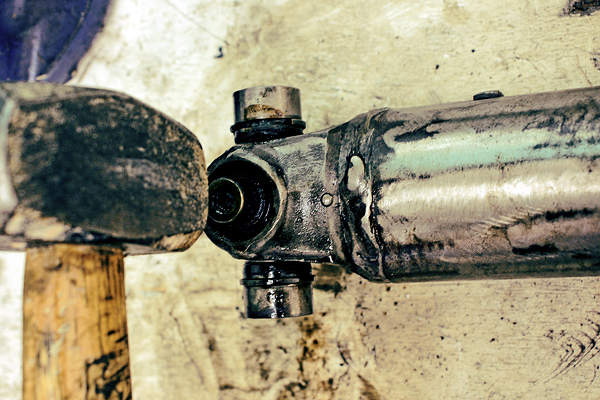

Now to remove the other cap. First whack it back into starting position. Put the larger socket on the other side and the smaller socket over the u joint arm with no cap. Again hit the smaller socket to drive the u-joint out into the larger socket. Then remove the cap.

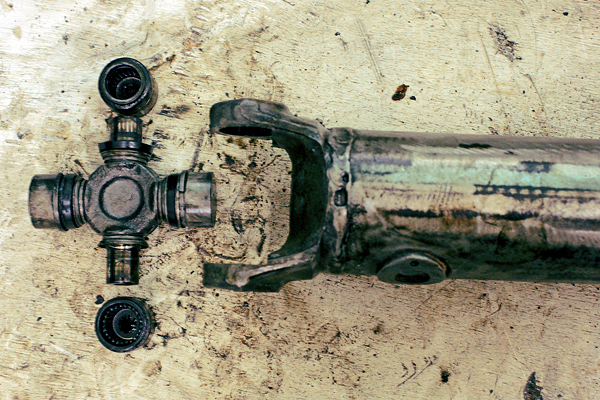

The u-joint will now be able to slide out.

This was for the rear diff side of the drive shaft. The trans side is exactly the same, just needs to be done twice over.

Really enjoyed your web site and the progress of your ’67 Firebird. One thing I want to do before I get too old is to restore an older car and recently bought a house with a garage big enough to do so. You’ve inspired me to start looking for that project car. Great site, great work, can’t wait to see the finished product, I’m sure it’ll be awesome….what color are you planning on painting your firebird?

Cheers for the compliments. You should definitely bring an older car back to the road, not only great fun, it’s very rewarding – in many ways.

I don’t know about my colour yet… long way off… nothing bright is all I know right now. Dark black perhaps…

Do you have a certain project car in mind?

I really enjoyed viewing your progress thus far. I’m not quite as far as you are on my ’67 Firebird project, and I haven’t documented anything. I’m recharging my digi camera battery as I type!

I just bought a welder, but need to get some experience under my belt before I trust myself to replacing the quarters. I did want to ask what mfg you bought all of your repro parts from. I’ve heard positive comments about Goodmark. Any thoughts or suggestions?

I’m not sure what to do now that I’m down to the tub. There is a very thick undercoating on the underside of the tub. I don’t think it’s factory. I may need to break down and take it in for media blasting ($$$).

I’ve bookmarked your site so that I can check in every so often. Keep up the great work!

John