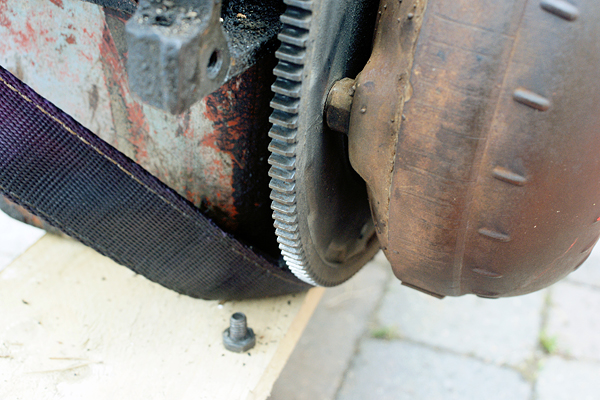

Getting ready to mount the engine for a rebuild. So, with it still on the crane had to remove the torque convertor and flywheel (AKA flex plate).

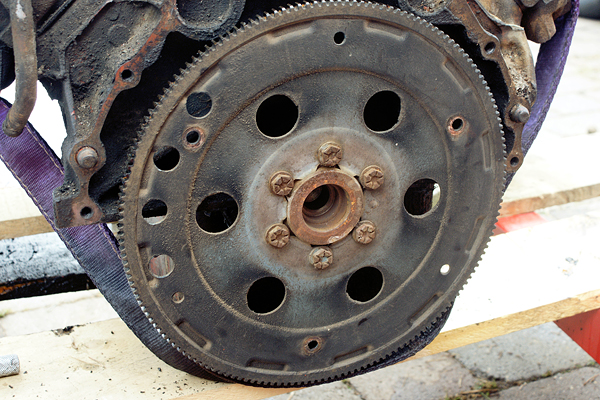

It is held on by 3 bolts, and access is limited. Found one place (the low left as you look at the flywheel) that a socket would fit and also hit against the side of the engine to stop the torque converter rotating as force is applied. To reach the other bolts it’s needed to rotate the fly wheel and torque converter – it’s possible to do by hand.

Once the other 2 bolts are out the torque converter will be off.

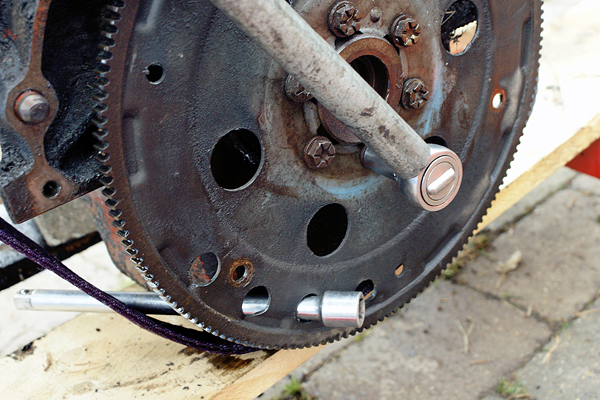

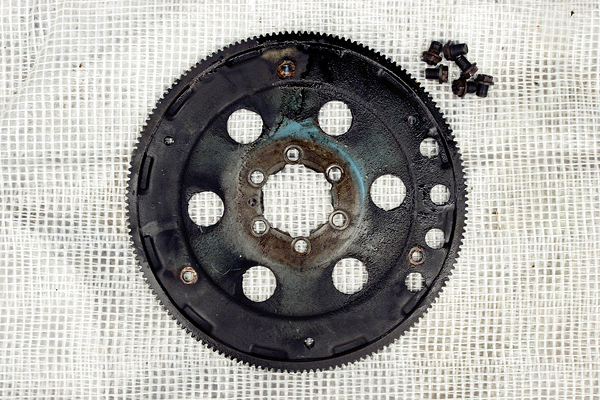

Now to get the flywheel off, this is held tightly in place by 6 bolts. To loosen the nuts you’ll need to stop the flywheel from rotating as you use the wrench. I just slid a socket extender bar through an access hole and hoped it hit something and stopping the flywheel from spinning – it did, it made contact with the oil sump. Then used a socket and an extender bar.

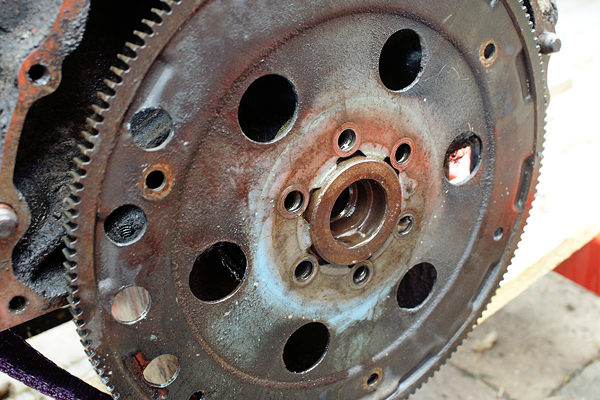

Once the bolts are out the flywheel will easily slide off.

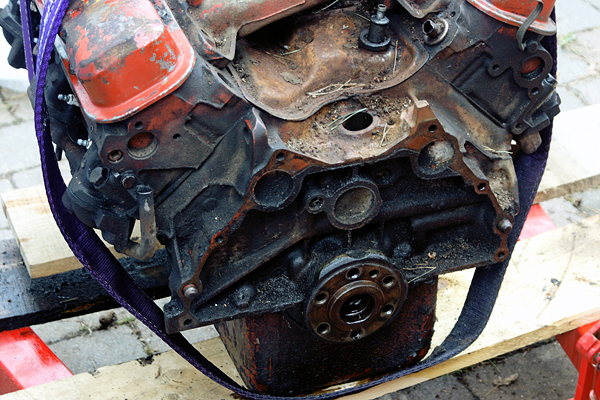

The engine ready for mounting:

No comments yet.